However, having options allows users to further explore and experiment to enhance their designs in ways previously unimaginable. Colors for natural woods, paints, and stainsĬreators might already have a firm handle on their material design.

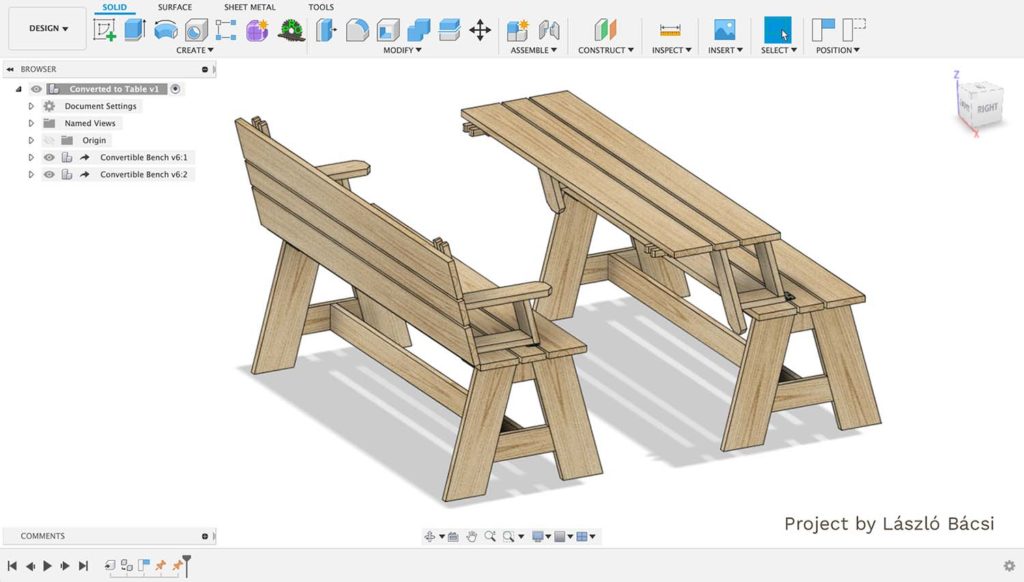

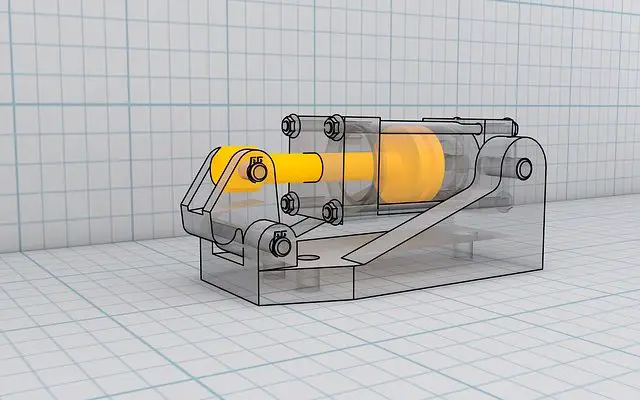

Once a design has been created in a CAD program, woodworkers may adjust the following elements of their design as needed before prototyping and manufacturing: Typically, woodworkers take a 2D drawing and translate it into woodworking plans or a cut list, and finally a 3D design. Colors and grains are also hard to represent accurately with simple drawings. Woodworkers must find a way to inject realism into their design process. Without 3D modeling software for woodworking, one might not be able to assess how a design may look in its ‘natural habitat’ before building. Translating that concept into a workable sample, and iterating is also critical. The Benefits of 3D Woodworking Design Softwareīrainstorming is merely half the battle when it comes to product creation. These factors will influence how a design comes together - and how it’s bolstered. For example, a rocking chair is clearly used differently than a wooden knife handle.

Creating a product that is well thought out requires planning and sound execution.

That said, these wooden creations don’t just suddenly materialize. Complexity, material design, and finish distinguish one project from the next. Woodworking is a passion for many worldwide, and it has undoubtedly become more popular as individuals look for ways to sharpen their minds as they stay at home. Learn how woodworking design software has changed the way woodworkers build and design their projects, from iteration to rendering.

0 kommentar(er)

0 kommentar(er)